Trim and Siding

Fascia, soffit and siding take time. Time on a ladder. I hate ladders!

Most of the work done here was completed over a couple of weeks, interrupted by work on the power (see below). You can see Joan Marie got a couple of photos of me at work, putting up the fascia. I used a combination of 8 inch Hardiboard for the facing and 1×4 that snugs up under the drip-edge flashing. The soffit uses sanded quarter-inch plywood, with a screened gap on the front and back of the shed roof for ventilation. FYI, I left enough felt overhanging when it was laid so that by the time I built out all the fascia materials it would all be covered.

The siding is LP SmartSide – their clapboard product. It’s lightweight and very easy to work with. I’ve never done clapboard siding before, so of course I started on the back side of the studio where any mistakes would be less obvious (the entire build has been this way, using the back side of the structure as my test bed for ideas). As of this writing, I’ve done all sides except for the front. In the one photo that Joan Marie took, I’m wishing I’d left a bit more of a setback from the fence line – things were a little crowded on that side!

The front has to wait until I do some custom work on the newly installed door. My goal is to take the door I purchased (a steel, right-hand in-swing, double door) and make it work better with the siding I’ve chosen. More on that later, but I’m pleased with the siding work so far!

Electrical

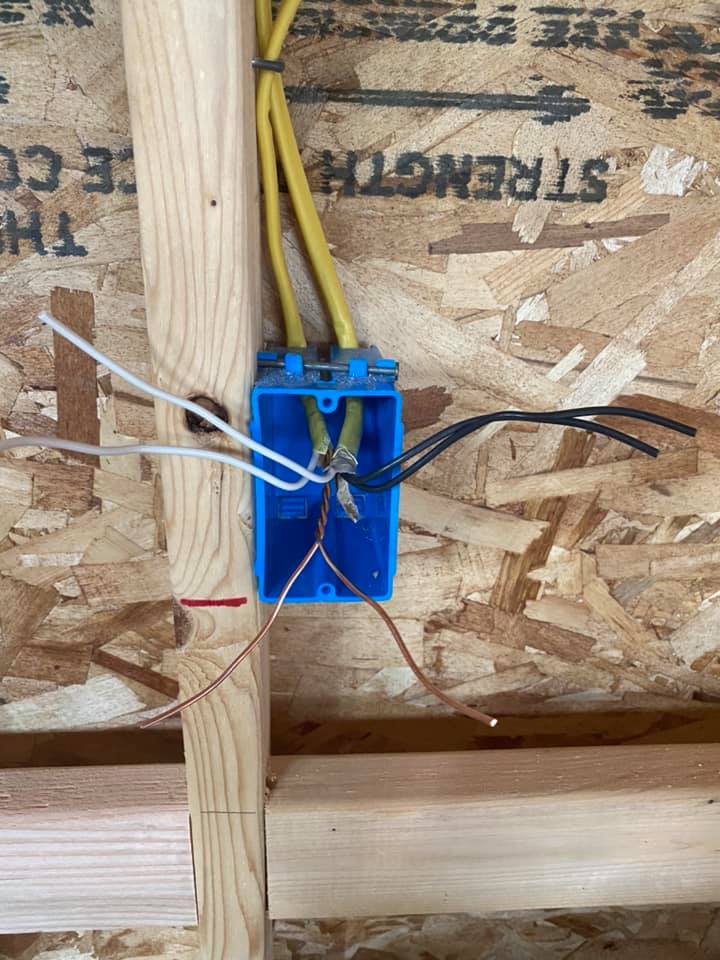

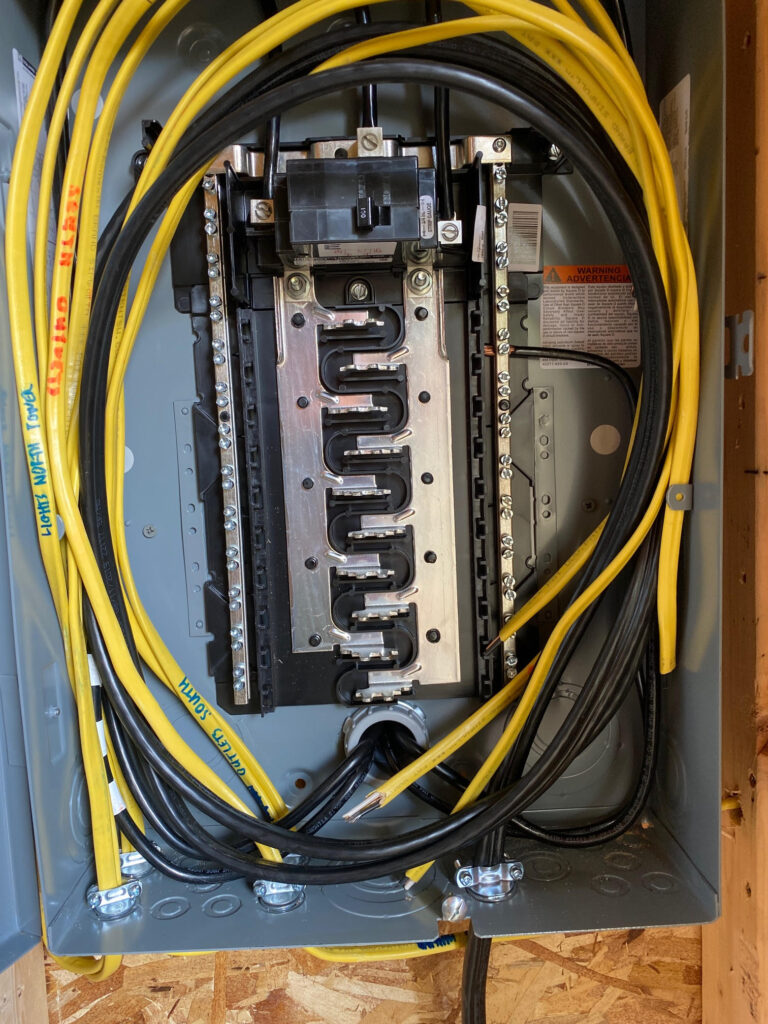

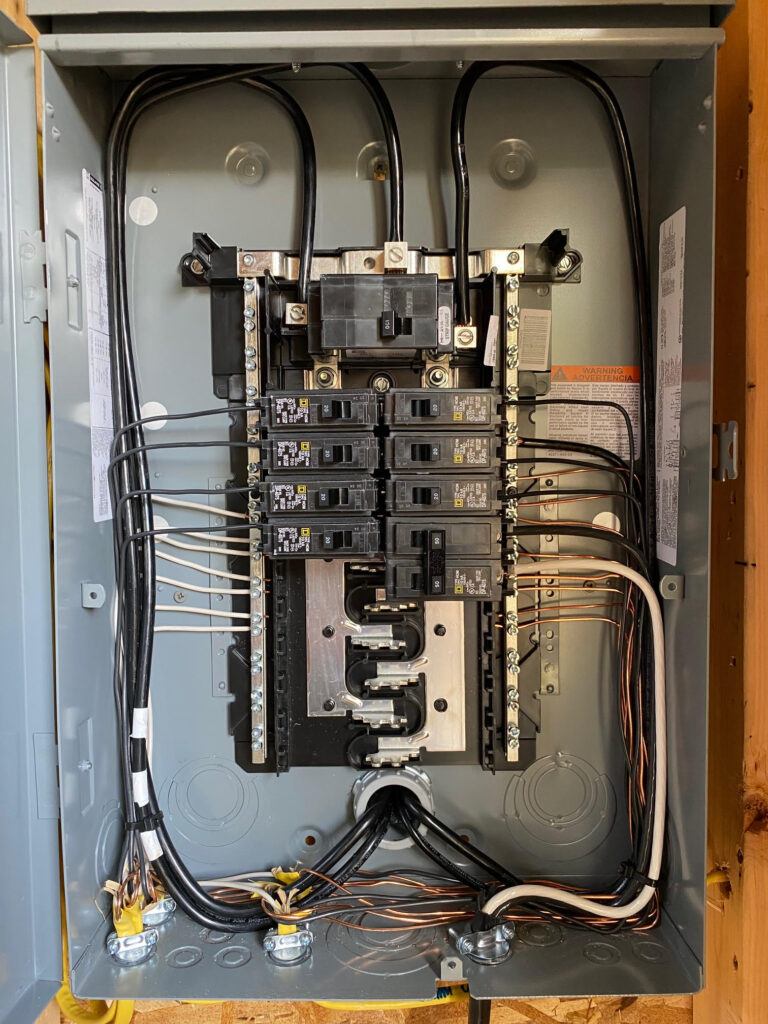

Electrical work has always scared me, having been shocked a couple of times. I was once knocked flat on my ass by a 220 line that was improperly grounded. However, this time, taking no chances, I had expert help from Steve Strapple and Victor Pagona. Steve helped with layout and design, and Victor helped inspect my work and connect the main panel to the sub-panel. Pulling 4 cables (three 3 gauge (THHN) cables, and one 6 gauge ground) through buried schedule 40 PVC is no fun, but we got it done!

The sub-panel pulls 100 amps, divided between the welder’s requirement for a 50 amp line and a 220 circuit, and the remaining 50 amps divided between all the 12 guage 110 lines – two circuits for lights, two circuits for 20 amp plugs, two circuits for outside lighting (one decorative at the front door, and the other task lighting for the welding area), and one dedicated circuit for the air conditioner.

In all, I was pleased with the work I was able to do and the guidance I got, and as Victor noted, the whole system is overbuilt. Call it a genetic flaw that I inherited from my father, but I overbuild everything!

Steps and doors

I had to go back and add these images. I’d forgotten to include them with the siding images. FYI – the door went up very easily – level, plumb and square. I like it very much. It’s a double door with a right-hand in-swing that opens up to the light switches on the wall. Not necessarily planned that way, but hey, as Victor said – tell no one!

The quality of the door is excellent for a box store special. It’ll have to be customized a little bit because the casing is designed for use with a much thicker wall. My next job is to modify the casing and rebuilt the brick molding so it goes better with the siding choices I’ve made. FYI, as far as modifying products, this is the only thing that I’ve had to change; otherwise, most everything else is stock. By the way, the offset of the door anticipates accommodating the inside walls and trim, and the threshold has treated lumber underneath that tie into the steps. As you can see, the threshold and top step meet perfectly. Even though the casing will be cut back, the threshold will remain extended.

Also, finally, Joan Marie and our neighbor Ben are both relieved that, after months of stepping up 16″ to get inside the structure, I’ve built a set of heavy-duty stairs with treated lumber, rated for ground contact. Even though it’s ground contact material, I still poured two small footers and embedded some Simpson straps into the wet concrete to pick up the 2×6 stringers I built. Again, overbuilt. Surprise. I’m debating on whether or not I want to add hand rails, but I’ve constructed the stairs in a fashion where I can always add them later, if I decide I want them.

Thanks for reading – that’s it for now!